Halogen-Free PCB

This article introduces what is halogen-free PCB and why it is necessary to choose halogen-free PCB.

Table of Content

- Halogen Free PCB

- What Are the Halogen Sspects?

- Why Is “halogen” Prohibited?

- Halogen Substitutes

- Disadvantages of Halogen-Free PCB

- Benefits of Halogen-Free PCB

- Halogen-Free Materials

- Halogen-Free PCB Production

- Halogen Examination Approaches

- Halogen Test Requirements

- Application of Halogen-Free Printed Circuit Board

When purchasing printed circuit board, you must stumble upon halogen-free circuit card. You may

have a concern in your mind: what is halogen-free PCB? Why do PCB suppliers create it? This write-up

will certainly address your doubts.

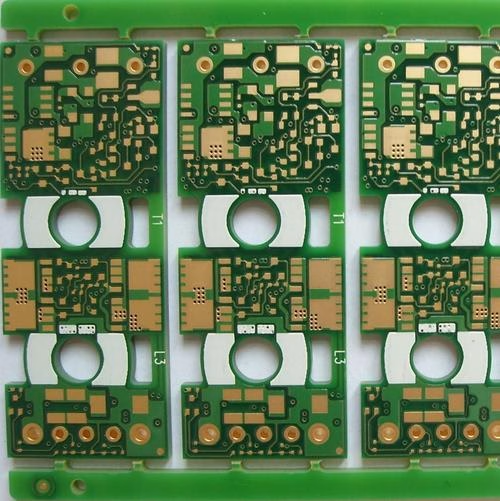

Halogen Free PCB

It is easy to understand from the literal meaning that halogen-free printed printed circuit board refer

to circuit card that do not contain halogen products or whose halogen material is minimal.

The standard for halogen-free printed circuit card is that the content of chlorine or bromine need to be

less than 900 components per million, and the halogen tool’s web content should be less than 1500

parts per million. Unlike lead-free PCBs, the halogen in halogen-free circuit card is not a material but

is a poisonous gas. It is not just dangerous to human health however likewise contaminated atmosphere.

As a result, we should choose halogen-free materials in PCB production. It benefits the atmosphere and

human health.

What Are the Halogen Sspects?

All of us recognize in middle school that halogen aspects are a big classification. It is a non-metallic

element composed of bromine, chlorine, fluorine, iodine, and other aspects. In the electronic devices

market, bromine and chlorine are often used in PCB materials, such as PCB laminates and prepreg layers.

Particularly, bromine has good flame retardancy and is used as a flame resistant for FR4 substrates.

This property is essential in many PCB applications.

Why Is “halogen” Prohibited?

According to relevant research study, halogen-containing fire resistant materials will release lots of

hazardous gases when melted, accompanied by an unpleasant smell, such as hydrogen halides, PBDE, and

PBDF. When hydrogen halides enter contact with water vapor in the air, acid rain is created. The sulfur

dioxide in the acid rain is corrosive and will pollute the environment. PBDE and PBDF are health hazards

that impact individuals’s wellness. The EU RoHS policies clearly specify thatPBDE and PBB flame

resistants are strictly limited.

Halogen Substitutes

Halogen-free circuits eliminate the reliance on halogen products by changing flame-retardant substances

and materials.

A lot of PCB makers make use of phosphorus and phosphorus nitrogen to change halogen PBB and PBDE.

Unlike halogens, phosphorus decomposes into polyphosphoric acid when it melts. After that, the

polyphosphoric acid dries and sets externally, developing a carbonized film that permits the surface

area of the protecting material to find into contact with the air, accomplishing a flame-retardant

impact. During the entire process, no hazardous or combustible gases are produced, and it can

additionally help extinguish the fire source through lack of oxygen.

Disadvantages of Halogen-Free PCB

• Costly:

Halogen-free printed circuit boards call for specifically created chemical resins, which are not as very

easy to generate as PBB and PBDE. So, firms that give coatings bill higher fees.

• Little Suppliers:

More manufacturers provide traditional PCBs than halogen-free printed circuit boards, which means that

you can purchase the variety of halogen-free circuits will be limited, so be cautious when trying to

find a supplier.

• The Manufacturing Procedure Is Much More Bothersome:

Without halogen-free, the PCB may come to be much more weak and vulnerable to white spots, making the

production of halogen-free printed circuit boards more difficult, specifically for making processes such

as solder mask manufacturing and look handling.

Benefits of Halogen-Free PCB

Halogen-free circuit boards make use of environmentally friendly products that are safe to human

wellness and beneficial to the atmosphere. Halogen-free PCBs additionally have the adhering to benefits:

• Eco-Friendly:

When managing halogen-free printed circuit card, they will certainly not produce dangerous compounds

such as halogen substances, reducing environmental pollution and complying with the halogen restriction

of EU nations.

• Protect the Health and Safety of Workers:

Halogen compounds are unsafe materials that release poisonous gases that are dangerous to the human body

at high temperatures. For that reason, using halogen-free products can minimize the hazardous gases

created during the welding and warmth therapy process, which not just protects the health and safety of

workers yet also boosts the safety of the workplace.

• Improve Circuit Board Insulation:

Halogen-free insulation materials are low-cost and reliable for non reusable electronic items. Because

halogens are changed by phosphorus or nitrogen, the polarity of epoxy resin is lowered, thereby

improving the circuit protect resistance and decreasing the break down force of the present.

• Lower Water Absorption:

For boards, low tide absorption influences boosting the integrity and stability of materials. Phosphorus

nitrogen molecules have less electrons than halogens. It is not easy to integrate with water molecules,

which means that halogen-free printed printed circuit board have a greater resistance to water

absorption. Although the scale of halogen-free printed circuit boards is a lot smaller than that of

PCBs, they can much better manage moist environments and scenarios.

• High Thermal Stability:

The nitrogen and phosphorus content in halogen-free circuit boards is more than that of average boards,

which raises the monomer molecular weight and Tg. Under heating conditions, the molecular wheelchair of

halogen-free products is less than that of standard epoxy resin boards. Consequently, halogen-free

printed printed circuit board have a reduced thermal growth coefficient, enabling them to hold up

against higher temperature levels. Since halogen-free PCB can endure high temperatures, it is more

suitable for high-power item style.

• Recyclable:

Recycling halogen-free circuit card can completely and efficiently utilize the steel materials in

circuit boards, such as gold, copper, silver, etc. Reusing these steel materials can minimize the demand

for limited sources, drive the growth of relevant firms, and give more employment possibility for social

skills.

• Enhance Market Competition:

Nowadays, increasingly more consumers like environmentally friendly and risk-free electronic items, so

halogen-free circuits can draw in more consumers, therefore enhancing the market competition of

ventures. Enterprises that make use of halogen-free products can mirror their worry for the environment

and incarnate their concern for the health and wellness of consumers and item top quality, which

contributes to the lasting advancement of ventures and can also boost brand name track record.

Quote for Halogen-free PCB Manufacture.

Halogen-Free Materials

Halogen is a product mainly used in laminate production or prepreg layers. Often, makers use these

materials in the solder paste used when putting together PCBs. Halogen substances are replaced with more

secure products in halogen-free circuits, as described listed below.

• Halogen-Free Laminate

In halogen-free PCB, laminate is used for the substratum. Generally, it is halogen-free FR4, where FR

stands for flame resistant material. Below are the choices for both fire resistant and resin.

Flame Retardants:

Several brominated compounds are made use of in conventional PCBs, such as PBB, PBDE, TBBPA, and HBCD.

In halogen-free printed circuit boards, these compounds are changed by the adhering to halogen-free fire

resistant ingredients.

• Aluminum (light weight aluminum hydroxide, light weight aluminum diethyl phosphinate)

• Phosphorus (phosphorus-based FR4 products, phosphorus-based flame retardants)

• Magnesium hydroxide

• Ceramics

• Melamine by-products

Epoxy Resin:

FR4 halogen-free laminates use epoxy material. It is normally a thermosetting polymer that supplies

mechanical security and insulation. Traditionally, this resin has halogens. In halogen-free boards, the

resins utilized are typically the following:

• Benzoxazine resin

• Bismaleimide triazine

• trifunctional epoxy resin

• Bisphenol Epoxy Plastic Ester

• Cyanate

• Polyimide

• Halogen-Free Flux

Halogenated solder paste or flux is made use of to construct circuit boards. This solder paste includes

a bromine activator and assists remove oxidation throughout the soldering process while additionally

offering sanding homes. In the halogen-free solder, change has actually been changed by safer options.

Halogen-Free PCB Production

The manufacturing procedure of halogen-free boards is similar to that of conventional PCB production,

other than that halogen-free materials replace halogen products. So, a couple of crucial steps are

explained right here.

• Product Prep Work

The substrate, copper foil, and solder mask need to all make use of halogen-free products, such as epoxy

material or polyimide.

• Laminated

Lamination is bonding each layer of the circuit right into an entire making use of the adhesiveness of

the PP sheet. Copper aluminum foil, bonding sheet (prepreg sheet), and various other products are

overlapped according to the procedure demands.

• Drilling

Drilling conditions are important to the high quality of PCB hole wall surfaces. Halogen-free

copper-clad laminates call for modification of drilling criteria contrasted to regular copper-clad

laminates because of their higher product strength.

• Antacid Resistance

Normally talking, the alkali resistance of halogen-free sheets is even worse than that of ordinary glass

fibers, so added care is needed throughout the etching procedure and the rework procedure after solder

masking. The soaking time in the alkaline stripping service should not be also long to stay clear of

white spots on the substratum. It is recommended that when revamping halogen-free solder mask boards, it

is best to make the first board, locate the most effective parameters, and then remodel in sets.

• Solder Mask

There are a range of halogen-free solder mask inks available on the marketplace. Their efficiency

resembles normal liquid photosensitive inks, and their procedure approaches are similar to typical PCBs.

Halogen Examination Approaches

There are several logical techniques to determine halogen web content:

• Burning Ion Chromatography: Burn the sample to release halogen for detection.

• X-ray Fluorescence Spectroscopy: Utilizing X-rays to boost Halogen discharge.

• Headspace analysis: Detection of halogen gases launched during heating.

• Wet Chemistry: Solution-Based titration methods.

• Total Organic Halogen Evaluation: Dimension of complete naturally bound Halogens.

Halogen Test Requirements

This conventional tests both substratums and ended up PCBs. The appropriate market screening criteria

consist of:

• IPC-4101— Verifying Halogen material in base laminates

• IEC 61249-2-21— Testing PCB laminates for halogen after manufacture

• UL 746A— Resolution of Halogens in laminated panels by flammability

• IEC 61249-2-41— Evaluating for total halogen material in laminating flooring resins

Application of Halogen-Free Printed Circuit Board

With the appeal of digital products, PCB has inhabited various areas. Halogen-free printed circuit card

has also increasingly appeared in the public eye. Its common usages are as complies with:

• High-end computers, robotics, and big web server farms.

• Cell phones and various other wireless gadgets.

• Signaling and transportation equipment.

• Consumer electronics such as TVs and video game consoles.

• Web traffic applications such as GPS and on-board computer system tools.

• Power stations and substations.

• Research laboratory.

• Distribution and arranging areas.

The Growth Prospects of Halogen-Free

Halogen-free printed circuit board is more secure, extra eco-friendly, and extra trustworthy than

conventional circuit card. It will certainly be the market criterion and the future advancement trend of

various makers. In order to develop much safer and extra cost-effective halogen-free sheets, an

increasing number of companies will invest heavily in halogen-free sheet research. We can anticipate

that more low-priced halogen-free boards will certainly appear in the market in the future.

Share This Post!

related Posts

Contact us

WhatsApp: +86-18123905375

Wechat: +86-18123905375

Email: sales@printedcircuitboardassy.com